Welcome to the Ultimate Guide to Runway Friction Testing: Ensuring Safe Landings! In this comprehensive guide, we’re going to delve into the charming world of runway friction trying out and its pivotal role in aviation safety. From expertise in the checking out process to exploring the technology and techniques concerned, we will equip you with the know-how to respect the meticulous efforts that move into making sure every flight touches down smoothly. Get ready to embark on an adventure through the skies and uncover the secrets and techniques at the back of secure landings.

Introduction

Understanding Runway Friction Testing

So, what exactly is runway friction trying out? Think of it as giving the runway a fitness check-up before each flight lands. Runway friction testing involves measuring the grip or traction tires of the runway floor to determine how well an airplane’s tires will grip the pavement in the course of landing and takeoff. It’s like ensuring your vehicle’s tires have sufficient tread earlier than hitting the street—besides on a much larger scale!

- Definition and purpose of runway friction trying out

- Measurement of grip or traction degrees

- Comparison to making sure tire tread for safe driving

The Crucial Role in Aviation Safety

Now, you might be thinking, why all of the fuss about runway friction trying out? Well, my friend, it’s all approximately protection. Picture this: a plane trying to land on a slippery runway with low friction—it is a recipe for disaster! Runway friction testing plays a pivotal role in aviation safety by presenting essential statistics to pilots and air traffic controllers. It ensures that planes can land and take off accurately, even in much less-than-ideal situations, like rain, snow, or ice.

- Preventing injuries and ensuring secure landings

- Providing vital statistics to pilots and air traffic controllers

- Importance of safe landings in diverse climate conditions

What to Expect in This Guide

So, what can you assume to research from this manual? Well, buckle up due to the fact we’re taking you on a comprehensive adventure via the arena of runway friction trying out! From understanding the trying out technique to its significance in improving aviation protection, we have got you included. Get prepared to dive deep into the science behind secure landings and benefit from a newfound appreciation for the meticulous efforts that cross into making sure each flight touches down smoothly.

- Comprehensive breakdown of the testing method

- Exploration of its importance in improving aviation safety

- Insights into the technological know-how in the back of safe landings

Understanding Runway Friction Testing

Definition and Purpose of Runway Friction Testing

So, what precisely can we imply whilst we speak approximately runway friction checking out? Well, consider it as checking the grip tiers of the runway surface, similar to how you’d take a look at the traction of your footwear on exclusive surfaces. The motive? Simple: to ensure that aircraft can land and take off adequately without slipping and sliding everywhere in the vicinity. It’s all approximately ensuring the ones rubber meets the street (or runway) moments are as easy as possible.

- Definition: Checking the grip tiers of the runway floor

- Purpose: Ensuring secure aircraft landings and takeoffs

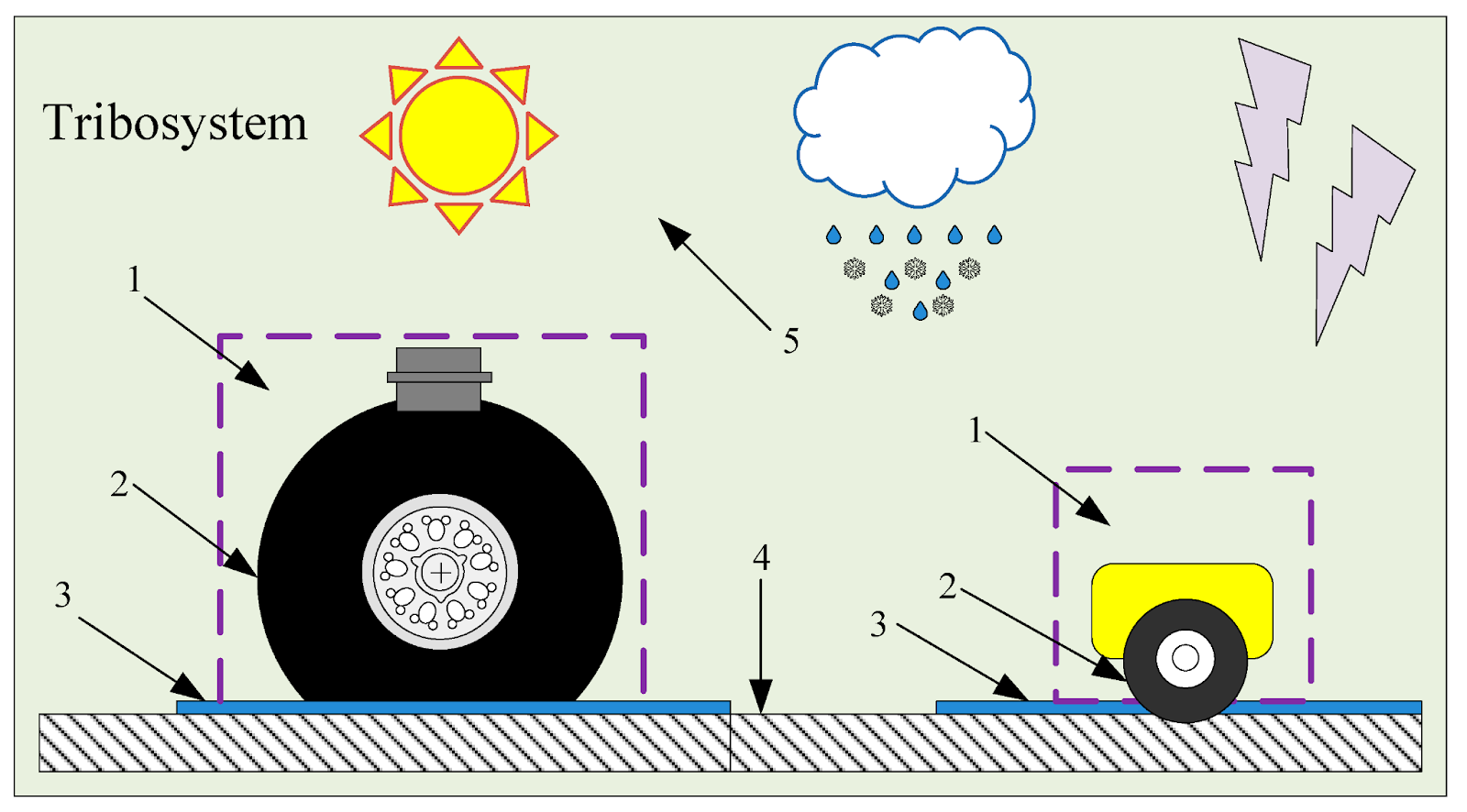

Types of Equipment Used for Testing

Now, let’s talk about equipment of the trade. When it involves runway friction checking out, there are plenty of gadgets inside the arsenal to get the job accomplished right. From specialized vehicles equipped with sensors to state-of-the-art friction measuring devices, each plays a critical function in assessing the runway’s grip tiers appropriately. It’s like having a group of professional detectives at the case, accumulating all the necessary clues to make sure a safe landing.

- Specialized vehicles prepared with sensors

- Sophisticated friction measuring gadgets

Factors Influencing Runway Friction

But wait, there’s extra to runway friction than meets the eye! Several factors can impact the grip levels of the runway surface. Weather conditions like rain, snow, or ice can considerably affect friction, making it important to live one step beforehand of Mother Nature. Other elements, inclusive of rubber deposits from aircraft tires or even the type of pavement surface, additionally come into play. It’s like a complex puzzle wherein each piece—regardless of how small—can have an effect on the overall picture of runway safety.

- Weather situations: rain, snow, ice

- Rubber deposits from plane tires

- Type of pavement surface

Importance of Accurate Friction Measurements

Now, permit’s talk turkey—why does all this remember? Accurate friction measurements are the holy grail of runway protection. They provide crucial facts to pilots and air traffic controllers, letting them make knowledgeable choices at some stage in landings and takeoffs. Whether it’s adjusting touchdown speeds or deciding on alternative runways primarily based on modern-day conditions, having reliable friction facts can imply the distinction among a smooth landing and a hair-elevating ordeal.

- Providing essential records to pilots and air traffic controllers

- Allowing knowledgeable decisions throughout landings and takeoffs

The Process of Runway Friction Testing

Preparing for Testing: Planning and Scheduling

Before we hit the tarmac, there’s a few foundations to be finished. Planning and scheduling are key to ensuring that runway friction trying out is going off without a hitch. It’s like mapping out your path earlier than an avenue experience—besides in this example, we’re plotting out whilst and wherein to conduct the tests. Factors like climate forecasts, runway utilization styles, and aircraft schedules all come into play. After all, we want to ensure we have the runway all to ourselves for a radical exam!

- Planning and scheduling checks for optimum timing

- Considering climate forecasts and runway usage patterns

Conducting the Tests: Step-by-Step Procedure

Conducting runway friction exams follows a step-through-step manner to ensure accuracy and consistency. First up, we deploy specialized cars prepared with sensors to degree the grip tiers of the runway floor. These cars make multiple passes over extraordinary sections of the runway, gathering information alongside the manner. It’s like mowing the lawn, besides as opposed to grass, we are trimming down uncertainty approximately runway safety!

- Deploying specialized cars geared up with sensors

- Making a couple of passes over different sections of the runway

Data Collection and Analysis Methods

Alright, we have collected all the facts—now what? Time to crunch the numbers! Data collection and analysis methods play a vital role in extracting meaningful insights from the uncooked data accrued for the duration of trying out. Sophisticated algorithms and statistical techniques assist us make sense of it all, identifying patterns and trends in runway friction levels. It’s like solving a puzzle, piecing together the statistics to color a clear image of runway conditions.

- Utilizing state-of-the-art algorithms and statistical techniques

- Identifying patterns and traits in runway friction tiers

Interpreting the Results: Assessing Runway Conditions

Drumroll, please—the instant of reality has arrived! With the information analyzed, it is time to interpret the effects and determine the runway conditions. This involves determining the friction coefficient, which suggests the grip tiers of the runway surface. Based on this data, we can gauge whether the runway is secure for aircraft operations or if additional measures are needed to improve friction. It’s like analyzing the tea leaves, deciphering the signs to make sure easy and safe landings for all.

- Determining the friction coefficient to assess runway situations

- Gauging the safety of plane operations primarily based on friction stages

Technologies and Techniques Used in Runway Friction Testing

Continuous Friction Measuring Equipment (CFME)

Ever heard of the Continuous Friction Measuring Equipment (CFME)? This nifty device is just like the Swiss Army knife of runway friction trying out. It’s mounted without delay onto plane touchdown gear, constantly tracking the friction degrees because the aircraft touches down. Think of it as an actual-time remarks machine for pilots, giving them immediate insights into runway situations. With CFME, pilots can alter their approach and touchdown techniques on the fly to ensure a clean landing each time.

- Installed immediately onto plane landing gear

- Provides real-time feedback to pilots

- Allows adjustment of technique and touchdown techniques

Mechanical Friction Testers

Now, allow’s talk old-faculty—mechanical friction testers. These trusty gadgets had been round for a while, using right old style elbow grease to measure runway friction. Mechanical friction testers are handheld gadgets that operators manually push along the runway surface, measuring the resistance encountered. While they’ll lack the bells and whistles in their excessive-tech opposite numbers, mechanical friction testers are reliable and simple, presenting correct readings that help keep our skies secure.

- Handheld devices manually driven alongside the runway surface

- Reliable and simple

- Provides correct readings

Continuous Friction Measuring Devices (CFMD)

Continuing on our journey through the world of runway friction testing, let’s shine a spotlight on Continuous Friction Measuring Devices (CFMD). These stationary devices are strategically positioned along the runway and constantly display friction tiers at some point of the day. It’s like having sentinels stationed along the runway, maintaining a watchful eye on situations around the clock. CFMDs provide valuable information to airport operators and air traffic controllers, assisting them make knowledgeable selections to ensure secure plane operations.

- Stationary devices strategically placed alongside the runway

- Continuously reveal friction levels

- Provide valuable facts to airport operators and air traffic controllers

Use of Specialized Vehicles for Friction Testing

Last but not least, let’s talk about the unsung heroes of runway friction testing—specialized motors. These beasts of burden are equipped with sensors and gadgets designed to degree friction ranges as they roll alongside the runway. With their sturdy production and particular instrumentation, specialized vehicles provide comprehensive facts that form the backbone of runway safety tests. It’s like having a cell laboratory right on the tarmac, accumulating essential facts to make sure easy and secure landings for all.

- Equipped with sensors and instruments

- Provide complete information for runway protection exams

- Act as a cell laboratory for accumulating critical facts

The Role of Runway Friction Testing in Ensuring Safe Landings

Impact of Runway Conditions on Aircraft Performance

Picture this: an aircraft approaching the runway for landing. Now, consider that the runway floor is slick with rain or blanketed in snow and ice. Not exactly the precise state of affairs, proper? Runway conditions have a significant effect on aircraft performance, affecting the whole thing from braking distances to control throughout touchdown. Without good enough friction, the plane may also struggle to return to a forestall competently, leading to probably hazardous conditions. It’s like looking to stop a car on an icy avenue—it’s going to be a bumpy ride without sufficient traction!

- Runway conditions affect braking distances and manipulate at some point of touchdown

- Inadequate friction can lead to hazardous situations

How Friction Testing Helps in Identifying Potential Hazards

Enter runway friction testing—a lifesaver in identifying potential risks earlier than they become safety risks. By measuring the grip levels of the runway surface, friction checking out gives crucial statistics to pilots and air visitors controllers. It allows them to investigate the runway’s suitability for touchdown and takeoff, mainly in unfavorable weather conditions. Think of it as shining a spotlight on capacity risks lurking underneath the floor, allowing for timely interventions to ensure secure aircraft operations.

- Friction trying out measures grip tiers of the runway surface

- Provides critical statistics to pilots and air traffic controllers

- Helps assess runway suitability for landing and takeoff

Examples of Incidents Prevented by Accurate Friction Testing

But don’t simply take my phrase for it—let’s communicate real-global examples. Countless incidents have been averted thanks to correct friction trying out. From avoiding runway overruns to stopping loss of control at some stage in touchdown, the records collected from friction assessments have performed a pivotal position in ensuring secure landings. It’s like having a mother or father angel watching over each flight, guiding pilots competently to their destinations even inside the maximum tough conditions.

- Preventing runway overruns and lack of manipulate for the duration of touchdown

- Data from friction tests plays a pivotal role in ensuring secure landings

Regulatory Requirements and Standards for Runway Friction Testing

Now, you might be questioning, are there rules and regulations governing runway friction testing? You bet! Regulatory groups like the International Civil Aviation Organization (ICAO) and the Federal Aviation Administration (FAA) have set up requirements and tips for carrying out friction tests. These requirements make certain consistency and accuracy in the checking out technique, in the long run enhancing aviation safety worldwide. It’s like having a playbook that outlines the nice practices for keeping our skies safe and sound.

- Regulatory groups establish standards and suggestions for friction checking out

- Ensures consistency and accuracy within the trying out method

- Enhances aviation protection worldwide

Challenges and Future Developments

Common Challenges Faced During Runway Friction Testing

First things first—let’s communicate approximately the boundaries that runway friction testers stumble upon in their quest for protection. From unpredictable climate conditions to versions in runway surface substances, there’s no shortage of demanding situations to navigate. Additionally, ensuring consistency and accuracy across special testing places may be a daunting venture. It’s like seeking to solve a puzzle with lacking portions—requiring careful making plans and interest to detail to overcome these hurdles.

- Unpredictable climate conditions

- Variations in runway floor substances

- Ensuring consistency and accuracy throughout distinctive trying out places

Advances in Technology to Improve Testing Accuracy

But fear not, because generation is here to save the day! Advances in the era have paved the way for stepped forward accuracy and performance in runway friction checking out. From state-of-the-art sensors and statistics analytics software to automated checking out devices, these innovations are revolutionizing the manner we examine runway situations. It’s like upgrading from a flip smartphone to a telephone—embracing new tools and techniques to beautify safety within the skies.

- Sophisticated sensors and facts analytics software program

- Automated testing device

- Revolutionizing the manner we verify runway conditions

Emerging Trends and Innovations in Friction Testing Methodologies

What’s next on the horizon? Emerging trends and improvements are shaping the destiny of friction testing methodologies. From drone-based total inspections to faraway sensing technology, these current techniques offer new insights into runway situations from specific views. Additionally, advancements in substance technology are leading to the improvement of subsequent-era runway surfaces designed to optimize friction and enhance protection. It’s like entering into the future, in which the possibilities are countless for ensuring easy and secure landings.

- Drone-primarily based inspections and remote sensing technology

- Advancements in substances technological know-how for subsequent-era runway surfaces

- Shaping the destiny of friction testing methodologies

Collaboration Efforts to Enhance Runway Safety Through Testing

Last however surely no longer least, collaboration is fundamental to enhancing runway protection through trying out. Airlines, airport authorities, regulatory groups, and era companies are joining forces to share facts, high-quality practices, and information. By pooling sources and know-how, these collaborative efforts are driving non-stop development in runway friction testing and ultimately enhancing aviation safety worldwide. It’s like constructing a sturdy foundation—running collectively to make sure that every flight lands safely, whenever.

- Collaboration amongst airlines, airport government, regulatory agencies, and technology vendors

- Sharing data, fine practices, and knowledge

- Driving continuous improvement in runway friction testing

Best Practices for Runway Friction Testing

Tips for Optimizing Testing Procedures

When it involves runway friction checking out, efficiency is the call of the game. One tip for optimizing testing approaches is to prioritize scheduling for the duration of off-peak hours to decrease disruptions to airport operations. Additionally, coordinating with air site visitors control to secure the runway, get admission to and clear airspace can streamline the trying out process. Remember, each minute counts on the subject of ensuring safe landings for all aircraft.

- Prioritize scheduling during off-top hours

- Coordinate with air traffic manipulate to stable runway access

- Streamline the checking out technique to reduce disruptions

Importance of Regular Maintenance of Testing Equipment

Just like your trusty vintage car, runway friction testing device requires ordinary protection to make certain ultimate overall performance. Routine inspections, calibration assessments, and preventive upkeep are vital to keep the device in pinnacle-notch circumstances. Neglecting upkeep can result in inaccuracies in friction measurements, doubtlessly compromising runway protection. It’s like changing the oil in your automobile—keeping the whole lot walking easily for dependable performance when it topics most.

- Routine inspections, calibration assessments, and preventive protection

- Ensure accurate friction measurements

- Prevent potential compromises to runway safety

Training and Certification for Personnel Involved in Friction Testing

Behind each a success friction test is a properly-educated and licensed group. Providing complete training programs and certification guides for personnel worried in friction testing is important to ensuring consistency and accuracy in the testing technique. From expertise testing protocols to running specialized equipment, right training equips personnel with the expertise and abilities needed to uphold aviation protection requirements. It’s like having a professional pilot at the helm—self belief in their abilities to navigate thoroughly thru any challenges that rise up.

- Comprehensive education packages and certification courses

- Ensure consistency and accuracy inside the checking out manner

- Equip personnel with knowledge and skills to uphold aviation protection standards

Case Studies Illustrating Successful Friction Testing Practices

Let’s wrap up our dialogue with some actual-world examples of successful friction checking out practices. Case studies from airports around the globe highlight the effectiveness of implementing first-rate practices in friction checking out. From identifying runway surface issues earlier than they amplify to stopping accidents through well timed interventions, these examples underscore the importance of following installed protocols and processes. It’s like getting to know from the experiences of others—gaining insights that help us navigate our own adventure in the direction of safer skies.

- Case studies highlight effectiveness of imposing excellent practices

- Identifying runway surface issues earlier than they strengthen

- Preventing accidents through timely interventions

Conclusion

Recap of the Importance of Runway Friction Testing for Safe Landings

Runway friction trying out is not just another object on the checklist—it’s the backbone of aviation safety. By assessing the grip tiers of the runway floor, friction checking out ensures that the plane can land and take off effectively, even in much less-than-best conditions. It’s like having a stable basis below our toes, offering the stability and confidence wished for every flight to touch down smoothly.

- Ensures safe landings and takeoffs in all situations

- Provides balance and self belief for every flight

Key Takeaways for Aviation Professionals and Stakeholders

For aviation specialists and stakeholders, the key takeaways from our manual are clear: prioritize safety exceptionally else. From optimizing checking out processes to preserving equipment and making an investment in education for personnel, every attempt contributes to the overarching purpose of ensuring secure landings. By working collectively and following high-quality practices, we are able to uphold the best requirements of aviation protection and preserve public acceptance as true within air travel.

- Prioritize safety peculiarly else

- Optimize trying out techniques and keep gadget

- Invest in training for personnel

Encouragement for Continuous Improvement in Friction Testing Practices

But our adventure does not stop here—a way from it. As generation advances and new challenges rise up, there may be continually room for development in friction trying out practices. Let’s embody a mindset of continuous development, seeking out modern answers and staying ahead of the curve. By constantly evolving and adapting to converting situations, we will make certain that our skies remain secure for generations to return.

- Embrace a mind-set of continuous development

- Seek out revolutionary answers and stay beforehand of the curve

Call to Action for Further Exploration and Implementation of Best Practices

So, fellow aviation enthusiasts, I leave you with this call to motion: let’s keep our exploration and implementation of first-rate practices in runway friction trying out. Whether you are a pilot, air traffic controller, airport operator, or aviation fanatic, all of us play a critical function in ensuring the safety of our skies. Together, allows rise to the mission and upholds the very high-quality standards of aviation protection. The sky’s the limit!

- Continue exploring and implementing excellent practices

- Uphold the highest requirements of aviation protection

Frequently Asked Questions (FAQs)

- What is runway friction testing, and why is it important?

- Runway friction testing involves measuring the grip or traction levels of the runway surface to ensure safe aircraft landings and takeoffs. It’s crucial for assessing runway conditions, especially in adverse weather, to prevent accidents and ensure passenger safety.

- How often is runway friction testing conducted?

- The frequency of runway friction testing can vary depending on factors such as weather conditions, runway usage, and airport regulations. In general, testing is conducted regularly to ensure that runway conditions meet safety standards, with more frequent testing during inclement weather.

- What equipment is used for runway friction testing?

- Various equipment is used for runway friction testing, including continuous friction measuring equipment (CFME), mechanical friction testers, and specialized vehicles equipped with sensors. These tools help measure friction levels and assess the safety of runway surfaces.

- Who performs runway friction testing?

- Runway friction testing is typically performed by trained personnel, including airport maintenance crews, specialized testing teams, and sometimes external contractors. These individuals are responsible for conducting tests, analyzing data, and ensuring that runway conditions meet safety requirements.

- How does runway friction testing contribute to aviation safety?

- Runway friction testing plays a crucial role in aviation safety by providing essential data to pilots, air traffic controllers, and airport operators. By assessing runway conditions and identifying potential hazards, friction testing helps ensure safe aircraft operations, particularly during critical phases such as takeoff and landing.

Facebook: https://www.facebook.com/profile.php?id=61556242913524

Instagram: https://www.instagram.com/contentflyers0/

Twitter: https://www.twitter.com/contentflyers0/

Pinterest: https://www.pinterest.com/contentflyers0/

Reddit: https://www.reddit.com/user/contentflyers0

Medium: https://medium.com/@contentflyers0/